MIROPLAST launches co-extrusion profile manufacturing

Ukraine makes strides on the way to its well-deserved place in the European Union. We started integrating our Western neighbors’ values, social norms, and standards way back when Ukraine was only starting this journey. After all, they have a direct influence on our industry.

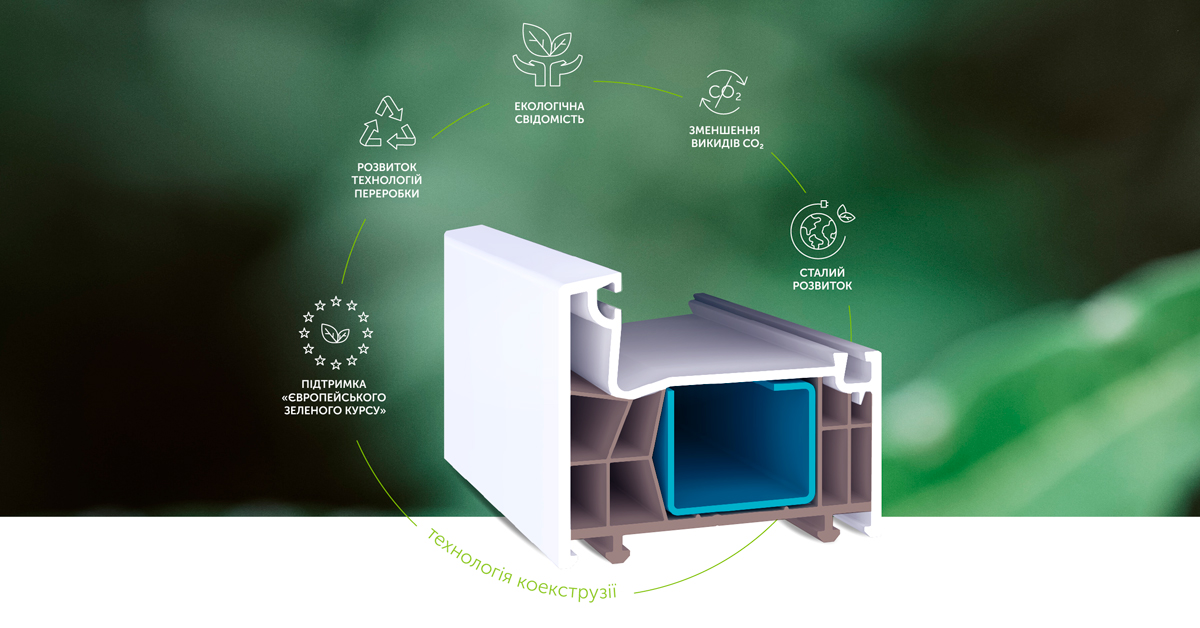

MIROPLAST supports the European community’s initiative to cut CO2 emissions through new recycling technologies. Our company has already finished the first stage of its production revamp, replacing some of the equipment with more advanced, co-extrusion-capable units. This way, we can make the internal part of our profiles from recycled materials and the external—from virgin ones.

The introduction of recycling technologies enables us to follow such corporate sustainability principles as:

- Reducing environmental pollution with plastic waste.

- Cutting energy consumption by introducing recycled materials, which are less energy-intensive to process than virgin materials. Recycling old PVC windows/doors and our residuals, we make our profile manufacturing more environmentally friendly and emit less CO2 in the atmosphere.

Many programs were launched as a part of the European Green Deal that envisions CO2 emissions falling by 55% against the 1990 level and reaching zero by 2050. By ratifying the Paris Climate Agreement, Ukraine affirmed its commitment to moving in the same direction. We celebrate the formation of environmental consciousness in our society and contribute to achieving our common goal.